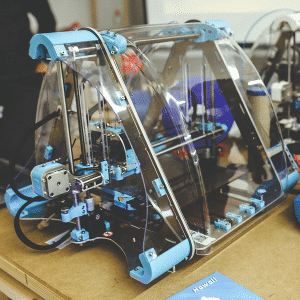

What would it be like if you had the ability to immediately recreate something you broke, lost or wanted to purchase?

No longer would you have to venture to the store, or wait days for delivery from an online casino.

While this isn’t reality today, it is something that is getting closer and closer each day thanks to the advancements being made in the field of 3D printing.

An Introduction to 3D Printing

To fabricate a product in the traditional manner, it requires a great deal of time, expense and effort.

In many situations, specialists must create unique molds, assemble countless components and construct items from several pieces.

The process typically involves the use of many different materials and the expertise of highly trained workers.

However, with 3D printing and rapid prototyping, some of the expense and time associated with creating new industrial and commercial items is reduced.

Rather than having to use a factory to create samples for testing, self-contained printers can make items from 3D CAD drawings.

When this method is used, items are printed a layer at a time.

This allows more control and creativity over the final shape than other, more traditional, construction methods.

Printing is also much faster. This reduces the creation process from days – or even weeks – to just hours for many items.

The History of 3D Printing

This is not a new technology. In fact, it was first thought up by Professor Herbert Voelker in the latter part of the 1960s.

His work resulted in the first real algorithms and mathematical models that described 3D parts.

The work he did is the basis for the majority of design tools being used today and what made rapid prototyping possible.

During the 1970s and 1980s, scientists utilized a series of machines and tools to try and automate object creation by cutting away at solid masses of metal or other materials based on some 3D design.

In the mid-part of the 80s, researcher Carl Deckard from the University of Texas came up with the method of printing objects one layer at a time.

The first machine to use this layering technique was created by 3D Systems in 1987. It is a method still used today.

The 3D Printing Process

The basic idea behind all 3D printers is the same.

With this process, the 3D CAD drawings are sliced into various layers that range from .09 to .25 millimeters in thickness.

The thickness will depend on the machine used. Every slice represents a single layer of the object being created.

Printers are unique, and each one uses different materials and binding processes.

However, usually, a metal, nylon, powder or ceramic is used as the base and then fused into the pattern for the layer being created.

Once completed, the machine moves to the next layer until finished.

What’s to Come in the Realm of 3D Printers?

This is an industry that is moving in several different directions all at once.

It is believed that it is going to continue to expand into many areas in the future.

While all industries are going to be able to benefit from this technology in one way or another, it is believed that some of the most promising areas include customized consumer products, custom parts replacement, and medical applications.

As materials improve and the costs drop, more applications will be discovered.

One of the greatest areas of potential growth for 3D printing is, without question, the medical field.

Researchers have just begun to work with the idea of creating artificial bones, but the process may be able to be used for much more in the future.

Another area of expansion for 3D printers is in the industry of replacement parts.

It is thought that soon, you will be able to get a new screw for your laptop or a new piston for your car just by printing it.

This eliminates the need to find the part, pay to have it shipped to you and then having to wait for weeks for it to arrive.

This benefits individuals, as well as mechanics.

An intriguing area of 3D printing benefits is in customized food production. Some companies are creating low resolution, low-cost options capable of printing models made out of granulated sugar.

Soon you may see edible items such as centerpieces, novelty lollipops, custom candy gives and other edible items emerge.

Right now, it is still unclear how far 3D printing may go in the future. However, it is definitely something to watch.